Hougen FAQs

Get answers to frequently asked questions.

Get answers to frequently asked questions.

Can I order directly from you?

No Hougen sells through authorized distributors. Please visit our distributor locator or call for help in finding a distributor in your area.

Do you sell online?

No Hougen does not sell directly online. Please visit an authorized distributor.

How do I become an authorized distributor?

Please contact your area sales rep or email info@hougen.com for more information.

How much does your product cost?

Please see your local distrubtor for current pricing info.

Where do you ship from?

Factory shipments in the US are from Swartz Creek, MI and Canadian shipments ship from Hamilton, ON.

What is a Magnetic Drill?

A magnetic drill is a specialized portable power tool used for drilling holes in steel and similar metals.

When do I use a mag drill?

It can be time-consuming and cumbersome to try to maneuver large steel or pipe into position at a stationary drill press or work center. A portable magnetic drill allows you to take the drill to the work piece, instead of trying to bring the work piece to the drill.

Where is a mag drill used?

What are the parts to a mag drill?

Which mag drill do I select?

Use this chart to determine which mag drill to use. The mag drill you select depends upon:

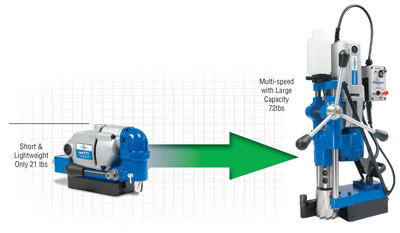

What is the size of a mag drill?

Available in a variety of sizes. From ultra low profile to large multi-speed models.

Magnet Adhesion?

Mag drills must magnetize to a solid surface. Magnetic strength is related to steel thickness. Minimum thickness is 3/8”. If the material is thinner, the magnet will not hold well. Clamp another piece of steel on top or below the thinner steel for stronger adhesion. Material that is clean and free from coatings will offer the best surface for the magnet. For non-ferrous materials use a Vac-pad™ (HMD904 & HMD905 only) or clamp a piece a steel on top of it.

Surface requirements for a mag drill?

A clean smooth surface will allow the magnet to ‘stick’ better. Situations where the magnet will have reduced holding power…

a) Material less than 3/8” thick

b) Coatings or paint layers on material

c) Chips, dirt, or grease between the magnet and the material

d) Curved surface (Surface should be flat. For pipe applications, a pipe adapter should be used.)

e) Magnet only partially on work surface

How do I keep my mag drill from slipping?

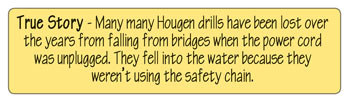

Make sure the drill’s magnetic base is clear of chips and debris and is securely attached to a clean surface. Uneven surfaces or large debris buildup prevents the magnet from obtaining optimal holding power, which can cause the drill to shift or lift during operation. A safety chain or strap also helps to prevent injury if the drill shifts. If it does shift or lift during the cut, it is very possible the cutter will break. Hougen mag drills have a built-in safety circuit that stops the motor when the drill lifts from the material. Always use a safety chain especially in horizontal & overhead positions.

Do I have to use coolant?

No…. BUT… Coolant increases annular cutter tool life dramatically. Hougen offers a number of different kinds of lubricant depending on the application. RotaMagic™ Concentrated Cutting Fluid is a biodegradable coolant that is mixed with water and used with a mag drills coolant system. Slick-Stik™ is a waxy lubricant. The user applies a glob to the inside and cutting teeth. Slick-Stik melts as the hole is made. Good for horizontal and overhead holes. RotaFoam™ is a foamy spray lubricant that is sprayed onto the cutter before each hole.

For best results use the mag drills coolant system. Spraying or squirting coolant at the cutter while it is turning does very little in helping tool life. Most of the coolant is pushed aside by the chips and flutes before it reaches the cutter.

*** Note: For Hougen drills without coolant bottles… fill the coolant reservoir through the slots in the arbor. This will hold enough coolant for approx. one hole.

What causes dull or broken cutters?

The primary cause of broken or prematurely dull cutters is a feed rate that is too slow. Slow feed rates will reduce the life of your cutter. Using a firm, steady feed pressure throughout the cut will maximize performance and extend tool life. You want to hear the drill motor working & the cutter producing long stringy chips that are being pulled from the hole. Look for a bird’s nest around the cutter.

Blue Chips = Big Problem

(Something obstructing the coolant system or you’re pushing too hard)

Make sure you have the correct cutter for the material. Stack-Cut for multiple layers.

Second reason why cutters break is movement of the drill or work piece. The cutter wall can easily be snapped if the drill and material is not held rigid.

Why does my slug stick?

Using lubricant or cutting fluid helps the slug to eject at the end of the cut. But when slug ejection becomes unreliable or the steel resists cutting, it probably means the cutter’s cutting edges are becoming dull. Re-sharpen or replace your cutter. Also make sure there are no chips inside your cutter which can hold up a slug. Also periodically check your ejection springs to maintain proper spring life.

How do I maintain my mag drill?

For the best performance, always maintain your drill as instructed in the operator’s manual. A list of op manuals can be found in technical support, if the manual supplied with your drill can not be located. Many mag drills feature a slide/gib/way system that requires periodic adjustments to maintain rigidity and optimal performance. Worn or damaged parts should be replaced to reduce the possibility of injury. The mag drill should be spot checked for damage prior to use. This will prevent costly repairs from running a damaged drill.

Is a safety chain or strap necessary?

YES! Your mag drill should always be used with a safety strap or chain especially in horizontal or upside down positions. Not only for safety of the operator but protecting your investment.

Why is my magnet lifting off the material?

Check your surface as outlined in surface requirements above. Also be sure the bottom of the magnet is free from chips and debris. A dull cutter can also push the magnet off the work surface. When drilling upside down, push on the handle closest to the arbor.

What should I do after drilling the hole?

What is positive slug ejection?

It is an arbor system that when the feed handles are retracted requires the slug to be pushed out after drilling a hole. The handles will not fully retract until the slug comes out of the cutter. All Hougen drills include this feature. It is a much more reliable method than a spring ejection arbor.

What is the proper feed rate for a mag drill?

A solid steady feed rate should be used to maximize cutter tool life. Listen to the motor. You want the sound of the motor to bog down a little. It should sound like its working. Do not over drive or under drive it as you can break or damage the drill. Also do not “peck” at the hole… meaning… feed the cutter down then let up, then feed the cutter down and let up. This can quickly destroy your tool.

Why do I have trouble drilling stainless steel?

Stainless steel is a beautiful material but it can easily work harden. Meaning… if you let off your feed pressure and allow heat to build up, the material can harden up to the point that it becomes almost impossible to continue. Use solid steady feed pressure, plenty of coolant and DO NOT let up to adjust your position.

Should I use a power feed mag drill?

Power feed drills offer a nice option for increased productivity. Many shops set up multiple drills for one operator to run.

Can I drill on the same material they are welding?

No. Drilling on the same material as they are welding can cause the magnet and circuit board to short out.

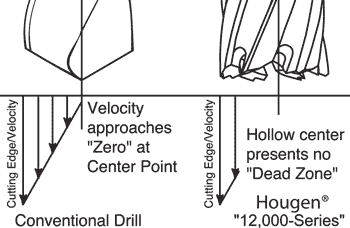

What is an annular cutter?

An annular cutter is a specialized bit for drilling through steel. Like a hole saw for wood, an annular cutter only cuts the outside edge of a hole. It produces accurate burr-free holes to close tolerances without pre-drilling or step drilling. It can drill a much larger hole and requires less force and time than a standard twist drill bit. As it turns, the cutter produces chips from the outside cutting edges and after cutting the hole a ‘slug’ (round chunk of steel from the center of the cutter) falls out.

Why use an annular cutter?

Annular Cutters offer superior holemaking capabilities. They cut faster, last longer, produce a better hole finish, a true round hole with very tight tolerances, can be re-sharpened and drills holes with less power and torque.

Which annular cutter do I use?

Use this chart to determine which annular cutter to use. The cutter you select depends on the diameter of the hole, the depth of cut and the type of material. A wide range of annular cutters are designed to cut through the following materials:

What are the parts to an annular cutter?

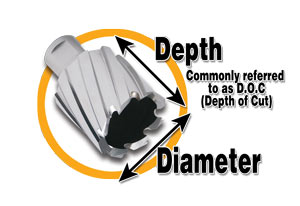

What is diameter and depth?

When determining cutter size, they are measured by depth and diameter. If you look at an actual cutter the depth is actually longer than what it is rated, (a 1″ cutter is really 1-1/4″) because this ensures the tool can drill all the way through the hole and allows extra length for resharpening.

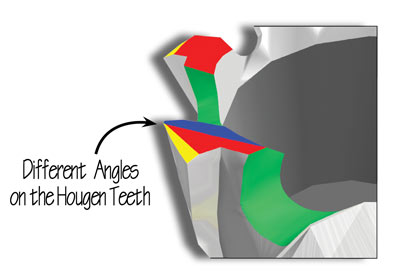

What is cutter geometry?

Angles on the cutting teeth make a big difference in how the tool performs. More precision angles increase the tool life and accuracy. Hougen tools have four different tooth geometries.

What is Standard vs. Stack-Cut Geometry?

Most annular cutters come with Standard geometry. These cutters are designed to cut through one piece of steel. They offer the fastest, cleanest hole producing a slug that looks like a ‘Top Hat’. When the job requires drilling two or more pieces of steel, cutters with stack-cut geometry must be used. The cutting teeth cut from the inside out producing a round cylinder slug.

Standard Geometry Slug

Stack-Cut Geometry Slug

Non-Coated vs. Coated Annular Cutters?

For 80% of applications a standard HSS cutter works. Using a coated or carbide cutter in these applications offers no additional benefit. Hard materials is where the benefit of using a coated or carbide cutter will pay off with increased tool life.

What is a pilot?

A Pilot is a large nail looking object that must be used when using an annular cutter. It serves three very important functions:

Pilots go through the center of the cutter. They retract up into the mag drill arbor as the hole is made. Pilots last a very long time and can be used with multiple sizes of cutters.

Do I have to use coolant?

No…. BUT… Coolant increases annular cutter tool life dramatically. Hougen offers a number of different kinds of lubricant depending on the application. RotaMagic™ Concentrated Cutting Fluid is a biodegradable coolant that is mixed with water and used with a mag drills coolant system. Slick-Stik™ is a waxy lubricant. The user applies a glob to the inside and cutting teeth. Slick-Stik melts as the hole is made. Good for horizontal and overhead holes. RotaFoam™ is a foamy spray lubricant that is sprayed onto the cutter before each hole.

For best results use the mag drills coolant system. Spraying or squirting coolant at the cutter while it is turning does very little in helping tool life. Most of the coolant is pushed aside by the chips and flutes before it reaches the cutter.

*** Note: For Hougen drills without coolant bottles… fill the coolant reservoir through the slots in the arbor. This will hold enough coolant for approx. one hole.

What causes dull or broken cutters?

The primary cause of broken or prematurely dull cutters is a feed rate that is too slow. Slow feed rates will reduce the life of your cutter. Using a firm, steady feed pressure throughout the cut will maximize performance and extend tool life. You want to hear the drill motor working & the cutter producing long stringy chips that are being pulled from the hole. Look for a bird’s nest around the cutter.

Blue Chips = Big Problem

(Something obstructing the coolant system or you’re pushing too hard)

Make sure you have the correct cutter for the material. Stack-Cut for multiple layers.

The second reason why cutters break is movement of the drill or work piece. The cutter wall can easily be snapped if the drill and material is not held rigid.

Why does my slug stick?

Using lubricant or cutting fluid helps the slug to eject at the end of the cut. But when slug ejection becomes unreliable or the steel resists cutting, it probably means the cutter’s cutting edges are becoming dull. Re-sharpen or replace your cutter. Also make sure there are no chips inside your cutter which can hold up a slug. Also periodically check your ejection springs to maintain proper spring life.

Why not use quick change cutters?

Quick change cutters are nice and convenient if you need to change sizes every hole or two. But using a mag drill with the two set screws to hold the cutter in place offers a couple of advantages:

Is a carbide cutter better than a HSS cutter?

Not necessarily. Carbide cutters are great tools and work good in most types of materials. But where they really shine is when they are used in hard or abrasive materials. They can be used in mild and structural steel but to get the best performance, carbide tooling needs to be turned at a much higher RPM than HSS cutters.

Aren’t all annular cutters pretty much the same?

That would be like saying all meat tastes the same. Hougen was the inventor of the mag drill annular cutter technology. Hougen® Cutters include the most features for the widest range of materials and benefits for long tool life. It takes a lot of extra time to machine and quality check the tools to ensure the customer gets what they expect. When purchasing a Hougen annular cutter, you are buying the highest quality annular cutting tool in the market.

Why do I have trouble drilling stainless steel?

Stainless steel is a beautiful material but it can easily work harden. Meaning… if you let off your feed pressure and allow heat to build up, the material can harden up to the point that it becomes almost impossible to continue. Use solid steady feed pressure, plenty of coolant and DO NOT let up to adjust your position.

Can I get a custom cutter made?

Absolutely! Hougen can solve your holemaking problems with creative solutions to help you get the job done, complete it faster and at a lower cost. We have helped thousands of customers with unique holemaking solutions. Give us a call or send us an email with your holemaking challenge. info@hougen.com

What hole puncher should I use?

Which unti you to use will depend on material being punched, thickness of material, diameter of hole and how far in from the edge of material. For further questions, contact Hougen Technical Services for proper punch selection.

What kind of material can I punch?

The Hougen-Ogua hole punchers are setup for A36 structural steel. They can punch other materials as weel. Contact Hougen Technical Services as to what other materials can be punched.

What kind of drill can I use?

Any hand held drill or drill press with a 3/8″ or 1/2″ chuck.

What RPM do I run the Holcutters or RotaCuts at?

Refer to the RPM Speed Chart below.

Suggested Speeds (RPM) for RotaCut™ Sheet Metal Cutters and Holcutter™

Do I need to use the speed reducer with Holcutters?

It is recommended for Holcutters over 1″ diameter.

What kind of can will fit into the paint shaker?

The paint shaker will hold one gallon, quarts, pints, aerosol and rectangular gallons containers.

How heavy of can of paint will I be able to shake?

The unit holds up to 11 lbs.

Where do I send my paint shaker for service?

If you paint shaker needs service please contact Hougen technical service first and return it to:

Hougen Mfg

3001 Hougen Dr

Swartz Creek, MI 48473

Attn: Repair