Magnetic Drill FAQ

Get answers to frequently asked questions. Don't see your answer...

email Hougen Technical Support

General Guide to Safe Mag Drill Operating Procedures

| What is a Magnetic Drill? A magnetic drill is a specialized portable power tool used for drilling holes in steel and similar metals. • They are used on the job site or in the shop • Also referred to as a mag drill, portable base drills, portable drill press When do I use a mag drill? It can be time-consuming and cumbersome to try to maneuver large steel or pipe into position at a stationary drill press or work center. A portable magnetic drill allows you to take the drill to the work piece, instead of trying to bring the work piece to the drill. • A portable magnetic drill may be used in any position—vertical, horizontal, or overhead (upside down) Where is a mag drill used?

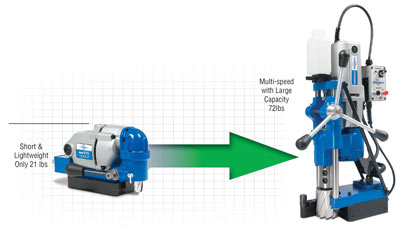

What are the parts to a mag drill?  Which mag drill do I select? Use this chart to determine which mag drillto use. The mag drill you select depends upon: • Application • Diameter of hole • Depth of hole to be drilled (D.O.C. Depth of Cut) • Drilling speed requirements • Number of holes • Work environment • Space / physical limitations • Type of material to be drilled What is the size of a mag drill? Available in a variety of sizes. From ultra low profile to large multi-speed models.

Mag drills must magnetize to a solid surface. Magnetic strength is related to steel thickness. Minimum thickness is 3/8”. If the material is thinner, the magnet will not hold well. Clamp another piece of steel on top or below the thinner steel for stronger adhesion. Material that is clean and free from coatings will offer the best surface for the magnet. For non-ferrous materials use a Vac-pad™ (HMD904 & HMD905 only) or clamp a piece a steel on top of it. Surface requirements for a mag drill? A clean smooth surface will allow the magnet to ‘stick’ better. Situations where the magnet will have reduced holding power... a) Material less than 3/8” thick b) Coatings or paint layers on material c) Chips, dirt, or grease between the magnet and the material d) Curved surface (Surface should be flat. For pipe applications, a pipe adapter should be used.) e) Magnet only partially on work surface How do I keep my mag drill from slipping? Make sure the drill’s magnetic base is clear of chips and debris and is securely attached to a clean surface. Uneven surfaces or large debris buildup prevents the magnet from obtaining optimal holding power, which can cause the drill to shift or lift during operation. A safety chain or strap also helps to prevent injury if the drill shifts. If it does shift or lift during the cut, it is very possible the cutter will break. Hougen mag drills have a built-in safety circuit that stops the motor when the drill lifts from the material. Always use a safety chain especially in horizontal & overhead positions. Do I have to use coolant? No.... BUT... Coolant increases annular cutter tool life dramatically. Hougen offers a number of different kinds of lubricant depending on the application. RotaMagic™ Concentrated Cutting Fluid is a biodegradable coolant that is mixed with water and used with a mag drills coolant system. Slick-Stik™ is a waxy lubricant. The user applies a glob to the inside and cutting teeth. Slick-Stik melts as the hole is made. Good for horizontal and overhead holes. RotaFoam™ is a foamy spray lubricant that is sprayed onto the cutter before each hole. For best results use the mag drills coolant system. Spraying or squirting coolant at the cutter while it is turning does very little in helping tool life. Most of the coolant is pushed aside by the chips and flutes before it reaches the cutter. *** Note: For Hougen drills without coolant bottles... fill the coolant reservoir through the slots in the arbor. This will hold enough coolant for approx. one hole. What causes dull or broken cutters? The primary cause of broken or prematurely dull cutters is a feed rate that is too slow. Slow feed rates will reduce the life of your cutter. Using a firm, steady feed pressure throughout the cut will maximize performance and extend tool life. You want to hear the drill motor working & the cutter producing long stringy chips that are being pulled from the hole. Look for a bird’s nest around the cutter. Blue Chips = Big Problem (Something obstructing the coolant system or you’re pushing too hard) Make sure you have the correct cutter for the material. Stack-Cut for multiple layers. Second reason why cutters break is movement of the drill or work piece. The cutter wall can easily be snapped if the drill and material is not held rigid.

Using lubricant or cutting fluid helps the slug to eject at the end of the cut. But when slug ejection becomes unreliable or the steel resists cutting, it probably means the cutter’s cutting edges are becoming dull. Re-sharpen or replace your cutter. Also make sure there are no chips inside your cutter which can hold up a slug. Also periodically check your ejection springs to maintain proper spring life. For the best performance, always maintain your drill as instructed in the operator’s manual. A list of op manuals can be found in technical support, if the manual supplied with your drill can not be located. Many mag drills feature a slide/gib/way system that requires periodic adjustments to maintain rigidity and optimal performance. Worn or damaged parts should be replaced to reduce the possibility of injury. The mag drill should be spot checked for damage prior to use. This will prevent costly repairs from running a damaged drill.

YES! Your mag drill should always be used with a safety strap or chain especially in horizontal or upside down positions. Not only for safety of the operator but protecting your investment.

Why is my magnet lifting off the material? Check your surface as outlined in surface requirements above. Also be sure the bottom of the magnet is free from chips and debris. A dull cutter can also push the magnet off the work surface. When drilling upside down, push on the handle closest to the arbor.

• Turn off motor • Ensure the slug has been ejected • Clean away any chips from the cutting tool & around and under the magnet What is positive slug ejection? It is an arbor system that when the feed handles are retracted requires the slug to be pushed out after drilling a hole. The handles will not fully retract until the slug comes out of the cutter. All Hougen drills include this feature. It is a much more reliable method than a spring ejection arbor. What is the proper feed rate for a mag drill? A solid steady feed rate should be used to maximize cutter tool life. Listen to the motor. You want the sound of the motor to bog down a little. It should sound like its working. Do not over drive or under drive it as you can break or damage the drill. Also do not “peck” at the hole... meaning... feed the cutter down then let up, then feed the cutter down and let up. This can quickly destroy your tool. Why do I have trouble drilling stainless steel? Stainless steel is a beautiful material but it can easily work harden. Meaning... if you let off your feed pressure and allow heat to build up, the material can harden up to the point that it becomes almost impossible to continue. Use solid steady feed pressure, plenty of coolant and DO NOT let up to adjust your position. Should I use a power feed mag drill? Power feed drills offer a nice option for increased productivity. Many shops set up multiple drills for one operator to run.

No. Drilling on the same material as they are welding can cause the magnet and circuit board to short out.

|

|