Technical Cutter Info

Guides for safe operation and best practices.

Guides for safe operation and best practices.

Why use Hougen® Cutters?

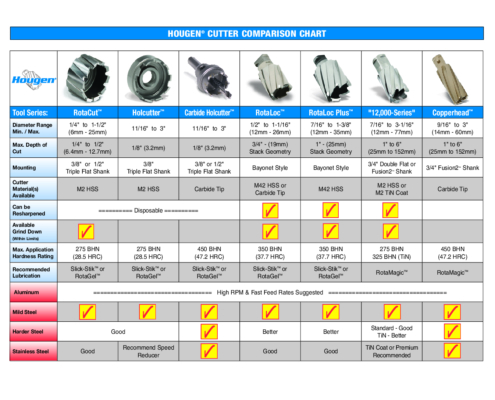

Cutter Comparison Chart

What is Stack Cut Geometry?

Most Annular cutters come with Standard Geometry. These cutters are designed to cut through one piece of steel. They offer the fastest, cleanest hole while producing a slug slug that looks like a ‘Top Hat’.

When the job requires drilling two or more pieces of steel, cutters with Stack-Cut geometry must be used. The cutting teeth cut from the inside out, producing a round cylinder slug allowing you to drill trhough mulitple pieces of steel at once. Using a standard geometry cutter to drill multiple pieces, you will have to stop and remove the slug before continuing on or risk breaking your tool. RotaLoc Plus™ cutters come standard with stack-cut geometry. Most other styles of Hougen cutters are available with stack cut.

Standard Geometry Slug

Stack-Cut Geometry Slug

Number of Teeth

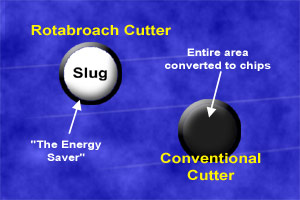

The Theory of Rotabroach

Other hole making techniques cut the entire hole into chips. The Rotabroach Annular Cutter hole making concept only cuts the periphery. The innermost portion or “slug” is the “energy saver”. We cut less material, make less chips. This translates into less unit horsepower. The larger the cutter, the bigger the power savings achieved.

Capacity

Rotabroach Cutters clearly require less energy, what is the productivity result?

1. Extend the capacity of the machine tool by using a Rotabroach Cutter larger than the typical size restriction of conventional drills for that machine, while staying within its horsepower rating.

2. Go faster. Most users opt for this choice whenever possible. This can be done by increasing the penetration rate. Rotabroach Cutters have more teeth than conventional drilling tools.

The utilization of more cutting edges/teeth with Rotabroach Cutters allows for increased penetration rates. Small Rotabroach Cutter sizes do not possess a vast difference in power consumption, since the area factor does not provide significant power reduction. More teeth, however, are an advantage for increased feed rates for all sizes:

IPM = FPT x NT x RPM

Where:

Even with high penetration rates, low chip loads per tooth are maintained. Forces on the teeth are kept low, reducing the tendency of tooth fracture and failure. Low thrust forces are the key element for applicability on thin walled workpieces and other nonconventional applications.

Coolant

Each Rotabroach Cutter is provided with a hole through the shank. This allows the flow of coolant through the center of the tool. A good flow of cutting fluid through the tool is important. It cools and lubricates the cutting edge, helps evacuate the chips, keeps the slug from expanding and helps eject the slug. See Hougen’s full line of lubricants including RotaMagic Concentrated Cutting Fluid

For Rotabroach Heavy Duty Industrial Cutters: A coolant system capable of delivering approximately 5 GPM at a minimum of 50 PSI is desired. Centrifugal pumps which may deliver a good flow at low pressure usually do not have the pressure capability to maintain the flow once the drill is engaged in the cut. They may deliver only a trickle in deeper holes when the coolant is needed most.

Other machine tool spindle adapters with coolant inducers are available from Hougen.

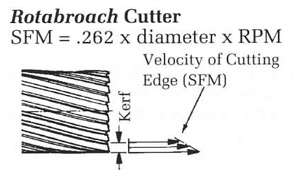

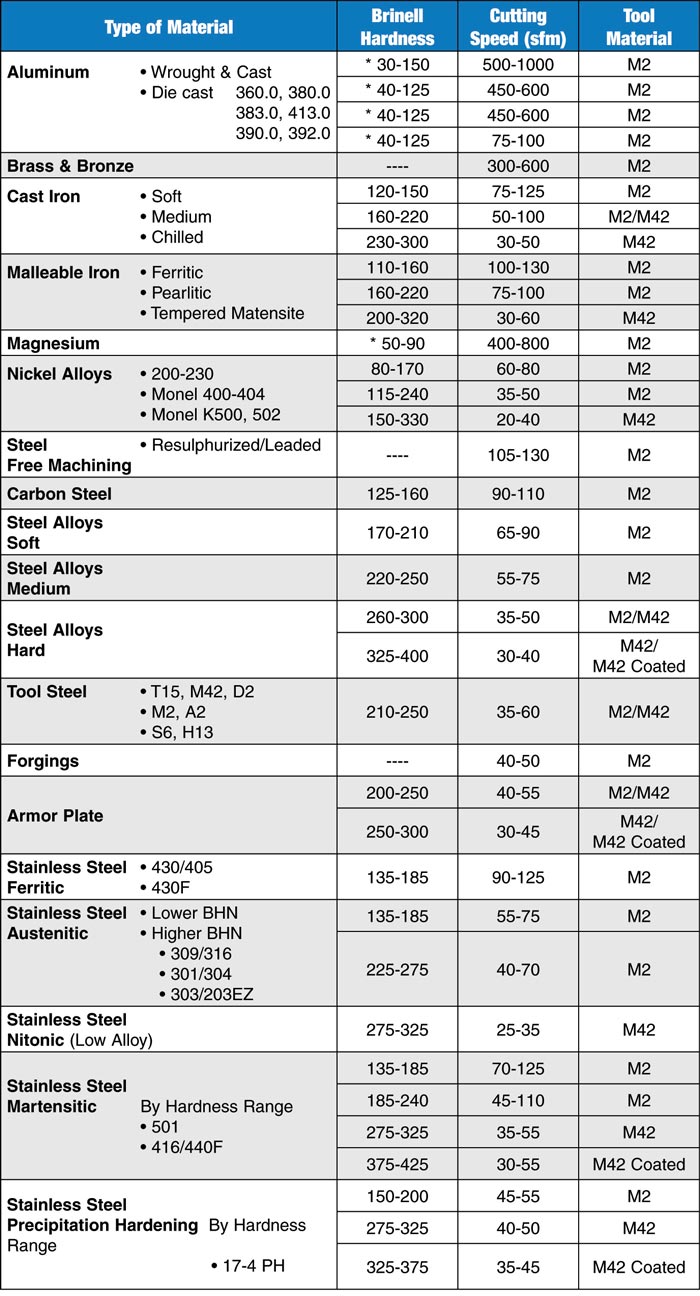

Cutting Speed

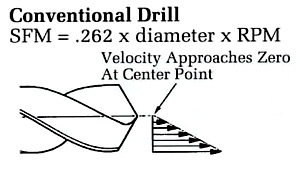

Cutting speed is the term used to express the velocity of the tool (SFM = surface feet per minute) as it cuts a specific material. Each material has an optimum range for its machinability with each cutting tool material (i.e. H.S.S. vs. carbide, etc.)

Use the following formula to compute a tool’s cutting speed:

Where:

SFM = .262 x diameter x RPM

SFM = .262 x diameter x RPM

Rotabroach Cutters provide a nearly constant tooth pitch. This pitch provides consistent tool life patterns for the entire range of diameter sizes in terms of lineal inches (inches of drill penetration).

These are only starting points. They will vary with application and workpiece condition.

Feed Rates

These are only starting points. They will vary with application and workpiece condition.

Difficult-to-machine materials will require reduced feed rates.

Please contact our Engineering Department regarding specific applications.

Hole Finish

Rotabroach Cutters provide similar hole textures as other cutting drills. Since a greater number of teeth are employed and tool life is extended, the surface finish obtained will generally be maintained longer. A slight spiral effect on the surface is noted under heavy feed rates. Light feeds and higher speeds will generally improve surface finishes.

Hole Size Tolerance

Rotabroach Cutters were originally designed as roughing tools to compete with twist drills and provide similar hole tolerance results. Many users have successfully applied Rotabroach Cutters to semi-finishing applications, reducing the number of passes from two or more to just one. A rigid machine tool and setup is required to produce holes to these specifications. Tolerances will vary with application and are impossible to pinpoint. Two hole tolerance probability curves are shown for dramatization, depicting typical results with a rigid machine tool and setup and a generalization of overall results from excellent to poor and unstable situations. Unstable conditions can lead to broken cutters.

Hole tolerance ranges are dependent on much more than the accuracy of any tool and its grind. Additionally, machine tool, workpiece, fixtures, selection of speeds and feeds, projection and type of application play an important function, determining overall results. Nominal cutter diameters are ground to a minus .001″ tolerance. On rare occasions as noted on the curves, cutters will cut undersize. This unfavorable condition will produce a burnished or reamed finish. Tool pressures can become so great that cutters may fracture. Typical reasons are:

1. If TiN coated tools are run too slowly, low friction effect allows the material to close-in.

2. Several titanium alloys and/or highly stressed materials exhibit a typical nature of closing-in on the cutter after the hole has been cut. In either case, corrective measures should be taken to eliminate the condition.

Please consult the Hougen Technical Sales Department.

Horsepower Comparison

Power consumption is a function of how fast a cubic inch of material is removed. This is broken down to area cut into chips or area factor (IN²) x how fast or feed rate (IPM) x how hard the material is to machine (K), or:

HP=(IN²) x (IPM) x K

For Steel: K=1

For Cast Iron: K=1/2

For Aluminum: K=1/4

The efficiency of a tool is also a consideration. The efficiency of the cutting edge varies only slightly with most tools and is included in the “K” factor, so its effect is negligible in most instances. TiN coating is found to be one exception where significantly greater efficiency can be realized.

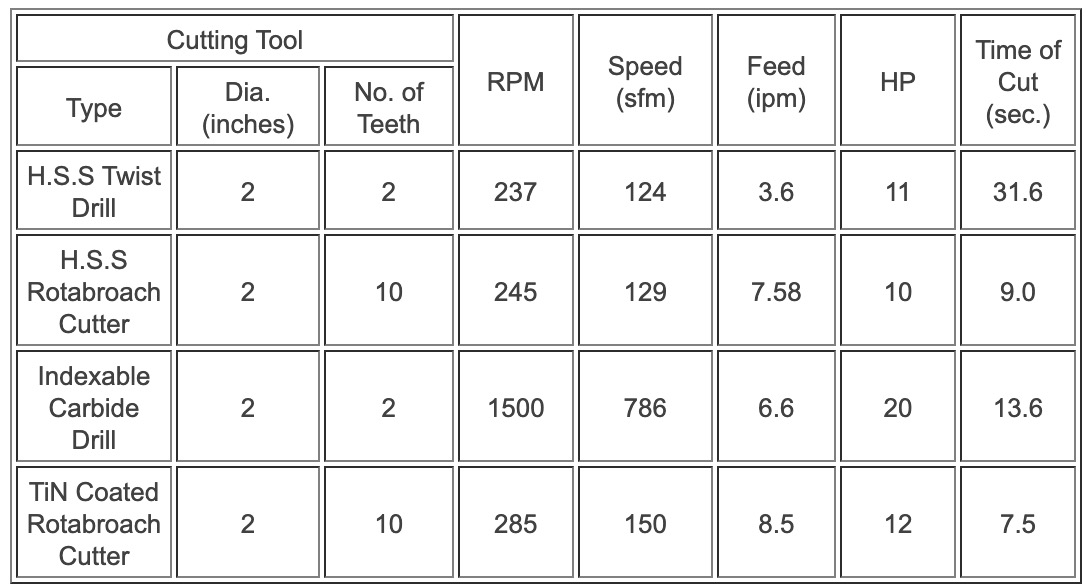

This table compares the performance of Rotabroach Cutters with two conventional holemaking tools. Note the lower horsepower requirements and significantly higher feed rates of the Rotabroach Cutter.

Lower Thrust

Thrust limitations are a concern on some machine tools with larger sizes of twist drills and spade drills. Rotabroach Cutters have much lower thrust requirements, and are seldom a factor when selecting equipment. An approximate thrust force value can be determined from the following equation:

T=.7 x WT x FPT x NT Kc

Where:

T = Approx. Thrust (lbs.)

WT = wall thickness (.188, .218, .264)

FPT = Feed per Tooth (.002 – .005 ipt)

NT = Number of teeth (Divide by 2 for “Hougen-Edge” geometry)

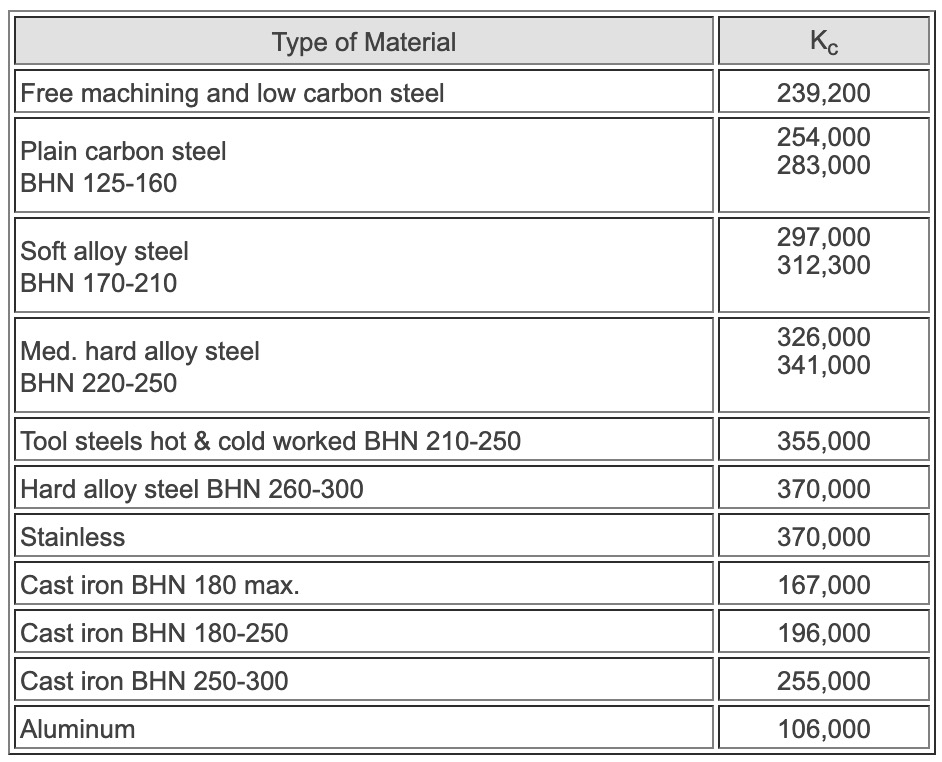

Kc = Machinability factor as related to tensile strength

Regrindability

Because of the number of teeth and other operational benefits, Rotabroach Cutters do not require regrinding as frequently as twist drills. When sharpening, only .015″ to .020″ is commonly required if the tool was pulled at a reasonable wear point. If allowed to continue and the edge is badly worn, burned, or chipped, more material will need to be ground away.Rotabroach cutters do not have an infinite regrindability as do twist drills which can be ground back till virtually no flute exists. Hole integrity and depth is lost.

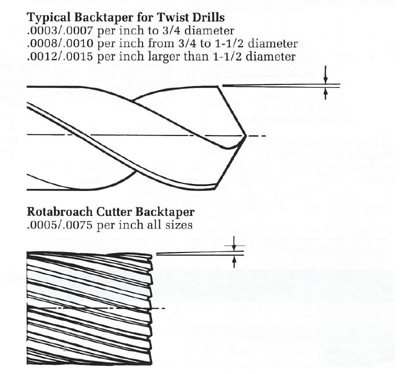

Rotabroach Cutters as well as twist drills have O.D. backtaper. As the end is reground, size is reduced. This becomes substantial when significant length is reground. Rotabroach Cutters have a limited regrind length. This length although limited, gives exceedingly long life, due to wear characteristics. By the time a Rotabroach Cutter has reached this length…it has paid for itself in increased production rates and quality of holes produced.

Regrinding Instructions

PLEASE NOTE: The angles mentioned in the videos below many have changed. Please refer to the op manual above for the most up-to-date angles and settings.